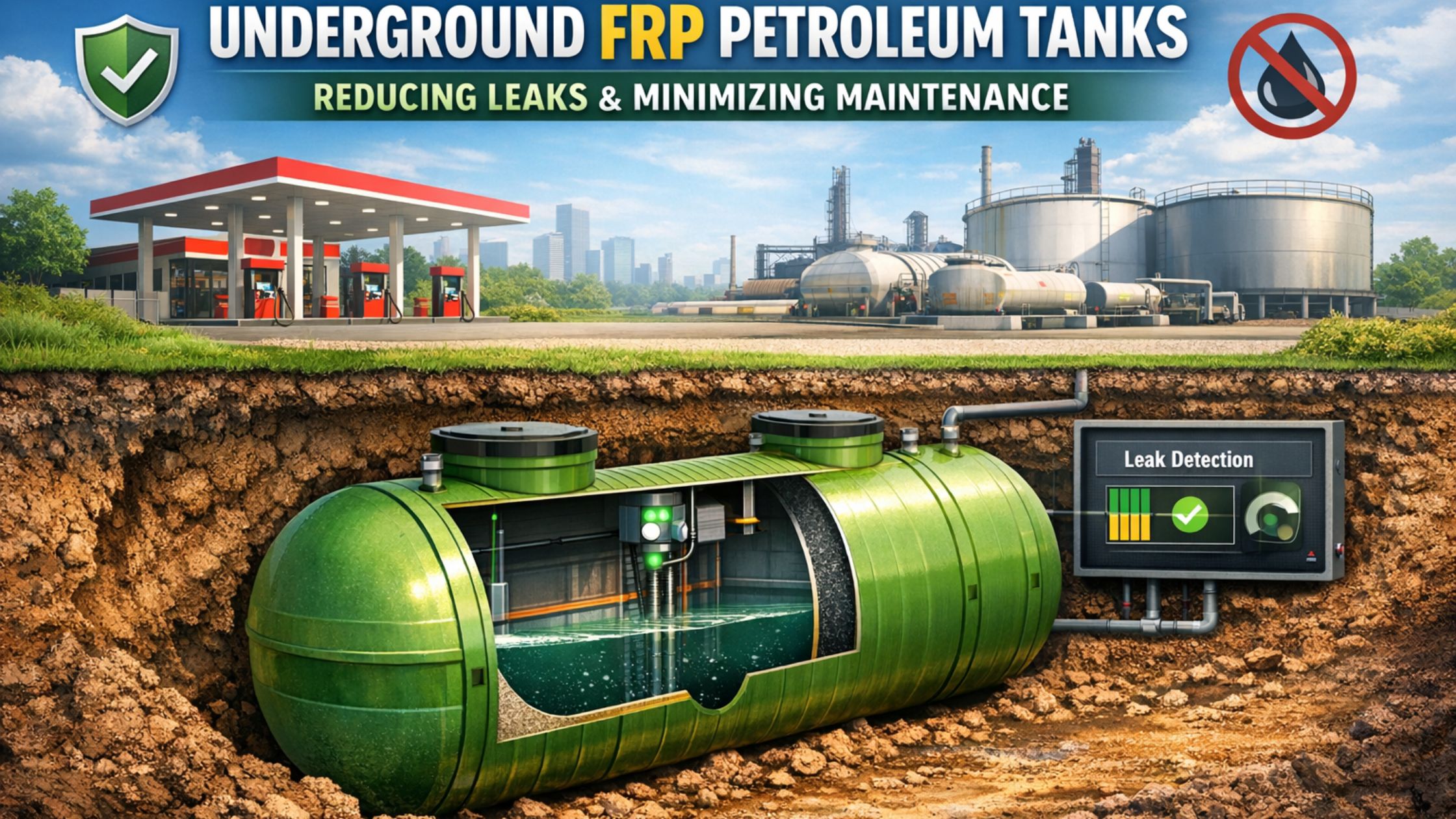

In today’s industrial and commercial landscape, underground petroleum storage is a critical requirement for fuel stations, oil depots, and large-scale industrial operations. However, traditional storage options such as steel or concrete tanks often face persistent issues—corrosion, leakage, and frequent maintenance—that increase both operational costs and safety risks.

To overcome these challenges, modern industries are turning towards Underground FRP Petroleum Tanks. Built with Fiberglass Reinforced Plastic (FRP), these tanks are designed to minimize leakage, reduce the frequency of repairs, and deliver long-term reliability for fuel storage.

Understanding Underground FRP Petroleum Tanks

Fiberglass Reinforced Plastic (FRP) is a composite material made from a polymer matrix reinforced with strong glass fibers. It combines lightweight durability, corrosion resistance, and structural strength, making it highly suitable for demanding storage applications.

Key structural features of underground FRP petroleum tanks include:

- Double-wall design: Offers an extra layer of protection against leakage.

- Corrosion resistance: Unlike steel, FRP does not rust or degrade when exposed to soil or petroleum products.

- Durability: With proper installation, these tanks can serve for decades with minimal maintenance.

These advantages make FRP tanks an ideal choice for long-term fuel storage solutions, ensuring safety and efficiency across industries.

Common Challenges in Traditional Underground Fuel Tanks

Industries relying on steel or concrete tanks often face recurring issues that compromise efficiency:

- Corrosion and rust: Steel tanks deteriorate quickly when exposed to moisture and petroleum products, while concrete tanks can develop cracks.

- High maintenance needs: Frequent inspection, cleaning, and patching are necessary to keep traditional tanks safe.

- Leakage risks: Cracks, rust spots, or seal failures can cause hazardous fuel leaks into the soil and groundwater.

- Increased costs: Repair downtime and environmental fines due to leakage incidents can significantly raise operational expenses.

These challenges make traditional storage methods less sustainable in the long run, prompting industries to adopt advanced alternatives like FRP.

How FRP Tanks Minimize Maintenance Needs

One of the biggest benefits of Underground FRP Petroleum Tanks is their low-maintenance design.

- Corrosion-resistant construction: FRP does not react with petroleum or soil chemicals, preventing the degradation that plagues steel and concrete.

- Lightweight yet strong: The material’s lighter weight makes transportation, handling, and installation easier while maintaining durability.

- Reduced maintenance cycles: FRP tanks do not require frequent repairs or internal coatings, saving industries both time and money.

- Industry case studies: Fuel stations, transport hubs, and municipal storage facilities report fewer shutdowns and reduced maintenance costs after switching to FRP tanks.

Over time, this means companies can focus more on operations and less on costly, unplanned repairs.

Ensuring Leak-Proof Underground Storage

Leakage is one of the most dangerous risks in petroleum storage. FRP tanks are specifically engineered to ensure leak-proof underground tanks through:

- Double-wall construction: The inner and outer walls create a secure barrier, with interstitial monitoring systems to detect potential leaks early.

- Sealed joints & fittings: High-quality sealing mechanisms prevent seepage.

- Compliance with safety standards: FRP tanks meet global certifications for underground petroleum storage, ensuring reliability.

- Performance in varied environments: Whether installed in dry, wet, or chemically active soils, these tanks deliver long-term reliability without compromising safety.

This ensures that businesses not only avoid environmental risks but also stay compliant with regulatory requirements.

Advantages of FRP Tanks for Long-Term Fuel Storage

For businesses looking for long-term fuel storage solutions, FRP tanks deliver clear advantages:

- Extended service life: FRP tanks last significantly longer than steel or concrete tanks under similar conditions.

- Reduced total cost of ownership: Lower maintenance and fewer replacements reduce costs over decades.

- Eco-friendly design: Their corrosion resistance ensures no contamination of soil or water, reducing environmental impact.

- Versatility: Widely used across industrial, commercial, and municipal fuel storage applications, FRP tanks adapt to diverse requirements.

This combination of performance and sustainability makes them the go-to choice for organizations aiming for safe and efficient storage.

Also Read – E20 Fuel and the Future of Petrol Storage: Why UL-Certified FRP Tanks from FibroGrats Are the Smarter Choice

Best Practices for Installing and Maintaining FRP Petroleum Tanks

While FRP tanks demand less maintenance than traditional alternatives, following best practices ensures maximum lifespan:

- Proper site preparation: Ensure stable soil and a secure foundation before installation.

- Regular inspections: Though less frequent, scheduled checks help in early detection of potential issues.

- Preventive maintenance: Use appropriate cleaning methods and avoid harsh chemicals that may damage seals.

- Safety protocols: Follow standard petroleum-handling guidelines during installation and operation.

- Professional guidance: Work with certified installers and service providers for installation and inspection.

Adhering to these steps allows industries to maximize the benefits of FRP technology.

Conclusion

The shift from traditional steel or concrete tanks to Underground FRP Petroleum Tanks represents a significant advancement in petroleum storage. By being leak-proof underground tanks that resist corrosion and require minimal upkeep, FRP solutions reduce operational costs while protecting the environment.

For industries seeking long-term fuel storage solutions, FRP tanks stand out as a future-ready choice—offering reliability, durability, and peace of mind.

Looking to safeguard your fuel storage with durable, eco-friendly solutions?

👉 Contact FGPL today to explore high-performance FRP petroleum tanks designed for your project’s needs.