India’s Shift Towards E20 Fuel

India is steadily moving towards E20 fuel—a blend of 20% ethanol and 80% petrol. This initiative, launched by the Government of India, is designed to cut down carbon emissions, enhance energy security, and boost domestic ethanol production. By 2025–26, most petrol sold across the country will be E20-compliant.

While this transition is a vital step for sustainability, it creates challenges for existing fuel storage systems. Petrol pumps, oil depots, and distributors using conventional metal tanks must prepare for the new era of ethanol-blended fuels.

How E20 Fuel Impacts Metal Storage Tanks

The move to ethanol-blended fuels requires a careful look at traditional infrastructure. Here’s why metal tanks pose risks:

- Corrosion Risk: Ethanol is hygroscopic, meaning it absorbs water from the environment. When water settles at the bottom of steel tanks, it leads to rusting, microbial growth, and contamination. Over time, tanks may leak—creating environmental hazards and financial losses.

- Phase Separation: Excess water leads to fuel stratification, where ethanol separates from petrol. This results in inconsistent quality and damage to engines. Worse still, operators lose usable stock, which impacts profit margins.

- Material Compatibility Issues: Studies by ARAI (Automotive Research Association of India) and global agencies reveal that metals like carbon steel and copper corrode faster when exposed to ethanol blends. Traditional rubber seals and plastics also degrade, leading to cracks, leaks, and safety hazards.

- Maintenance & Safety Concerns: To manage corrosion, fuel retailers must schedule frequent inspections, apply protective coatings, and drain water regularly. These stopgaps raise costs and increase downtime, making operations inefficient.

Why FRP Tanks Are the Future

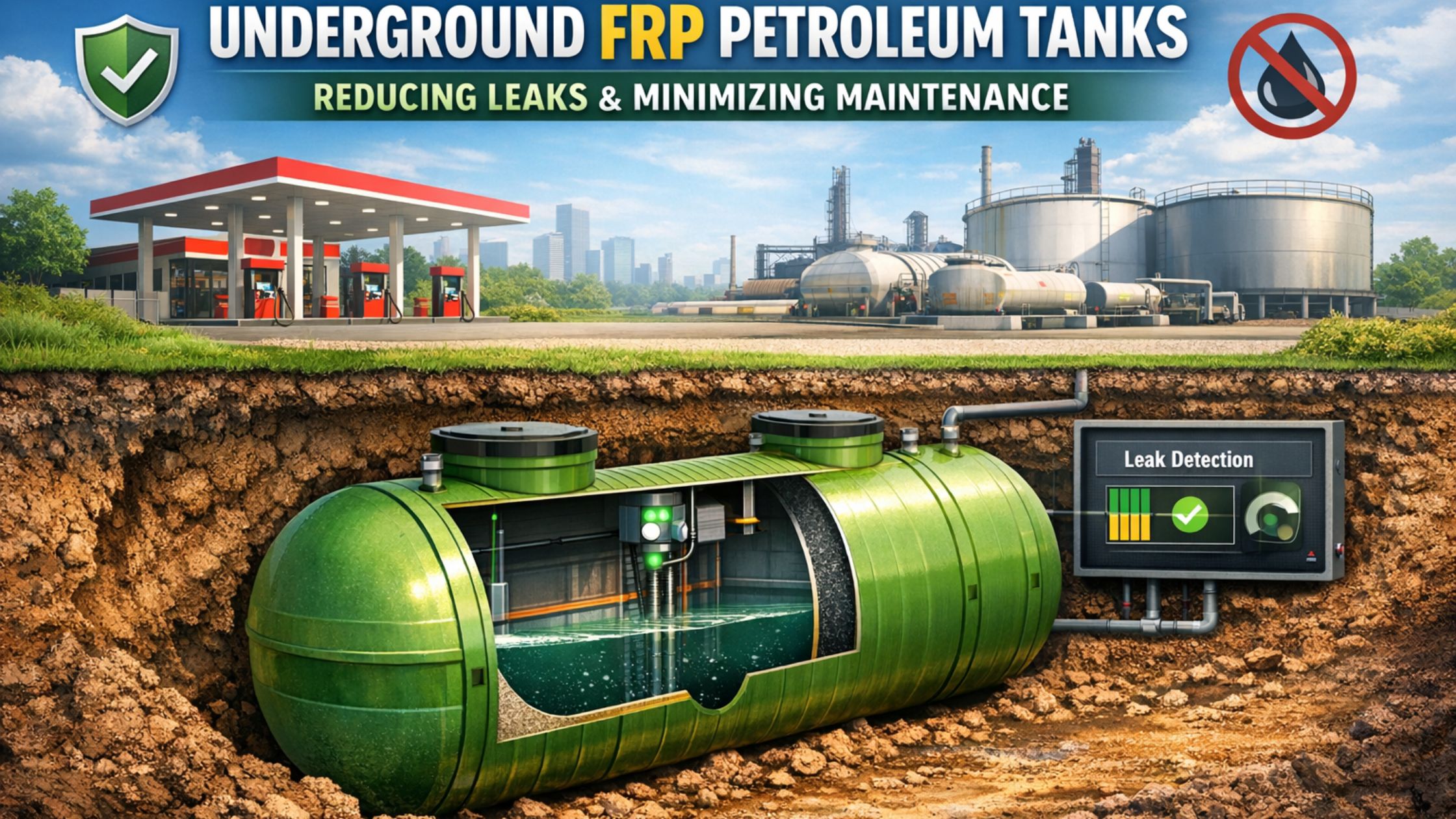

The solution lies in Fiberglass Reinforced Plastic (FRP) tanks. Unlike steel, FRP tanks are non-corrosive, lightweight, and engineered for ethanol compatibility.

Key benefits of FibroGrats’ UL-certified FRP petroleum storage tanks include:

- ✅ 100% Corrosion Resistance – With no metal parts, tanks remain unaffected by rust or microbial growth.

- ✅ Ethanol Compatibility – Advanced resins ensure safe storage of ethanol blends like E20.

- ✅ Long Service Life – Proven durability under India’s extreme weather and soil conditions.

- ✅ Leak-Proof Design – Prevents fuel seepage and groundwater contamination.

- ✅ Low Maintenance – No need for expensive anti-corrosion treatments.

- ✅ Global Standards – Certified by UL (Underwriters Laboratories, USA) for world-class safety.

Research-Backed Reliability

Both Indian and global research backs the case for FRP tanks:

- ARAI studies confirm that ethanol accelerates corrosion in conventional steel tanks.

- In Brazil, where E20 to E27 blends have been used for decades, fuel retailers successfully switched to FRP and lined tanks to manage compatibility issues.

- In the USA, ethanol blends up to E85 are widely used. Experience shows that long-term adoption requires tanks made with ethanol-compatible materials.

FibroGrats, with its UL-certified FRP tanks, brings this proven global expertise to Indian fuel retailers.

Practical Guidance for Petrol Pump Owners

If you operate a fuel station, preparation for the E20 era is crucial. Here’s a practical roadmap:

- Infrastructure Assessment: Inspect existing tanks for corrosion, water contamination, and seal degradation. Even minor rust spots can escalate quickly with ethanol-blended fuel.

- Short-Term Management: Temporary solutions like coatings or drainage systems can reduce risk but remain costly. They also require repeated application and do not eliminate the root cause.

- Invest in FRP Tanks: Upgrading to FRP petroleum storage tanks ensures long-term compliance with E20 requirements. This not only reduces costs but also protects fuel quality and customer trust.

- Future-Proofing for Higher Blends: India may adopt higher ethanol blends (E25 or beyond) in the future. By choosing FibroGrats’ FRP tanks now, you stay prepared for upcoming policy shifts.

The FibroGrats Advantage

At FibroGrats Pvt. Ltd., we specialize in UL-certified FRP petroleum storage tanks engineered for India’s evolving fuel market.

- Over two decades of expertise in FRP technology.

- Trusted nationwide for fuel, chemical, and water storage applications.

- Customized solutions for petrol pumps, depots, and industrial clients.

- Tanks designed specifically for ethanol-blended fuels like E20 and beyond.

With FibroGrats, you get more than just a tank—you get a future-ready solution that combines safety, efficiency, and global certification.

Why UL-certified FRP Petroleum Storage Tanks Matter

Not all FRP tanks are created equal. UL certification is a global benchmark for safety and reliability in the storage of petroleum products.

A UL mark ensures:

- The tank has passed rigorous testing for ethanol fuel compatibility.

- The design prevents leaks and environmental contamination.

- Operators can confidently meet both current and future regulatory requirements.

By choosing FibroGrats’ UL-certified tanks, you’re investing in long-term security for your business.

Future-Ready Fuel Storage in India

The government’s push towards E20 is more than an environmental initiative—it’s an industry-wide transformation. Fuel retailers who adapt early will save money, avoid downtime, and maintain customer confidence.

By upgrading to FRP petroleum storage tanks, you:

- Protect infrastructure against corrosion.

- Guarantee safe storage of ethanol blends.

- Reduce operating costs and stay ahead of compliance deadlines.

Conclusion: Preparing for the E20 Era

The arrival of E20 fuel in India is inevitable. The critical question is—is your infrastructure ready?

Switching to FibroGrats’ UL-certified FRP petroleum storage tanks ensures:

- Zero compromise on safety.

- Zero risk of corrosion.

- Zero disruption to your operations.

👉 Future-proof your fuel storage today. Contact FibroGrats Pvt. Ltd. for customized FRP storage solutions designed for the E20 era.