Introduction: Why Acid Regeneration Matters More Than Ever

Steel manufacturing keeps the world moving — from infrastructure and transport to machinery and everyday products. But behind the scenes, one process quietly ensures that steel production stays efficient, sustainable, and cost‑effective: acid regeneration.

As steel plants face rising environmental expectations and tighter cost controls, the materials used in acid regeneration systems are under the spotlight. Storage and process tanks, in particular, must withstand some of the harshest chemical environments found in industry.

This is where Fiberglass Reinforced Plastic (FRP) tanks have stepped forward as the preferred choice. Their corrosion resistance, long service life, and low maintenance needs make them a smart investment for any modern steel plant. At Fibro Grates Pvt. Ltd. (FGPL), we’ve seen firsthand how well-engineered FRP Tanks for Acid Regeneration Plants transform reliability and performance in acid regeneration and pickling operations.

Understanding Acid Regeneration Plants in Steel Manufacturing

What Exactly Do ARPs Do?

Acid regeneration plants (ARPs) recover and recycle spent hydrochloric acid used during steel pickling. Pickling removes mill scale and surface impurities from hot‑rolled steel, but over time the acid becomes saturated with dissolved iron and loses effectiveness.

Instead of disposing of this spent acid — which is costly and environmentally harmful — ARPs regenerate it. The process separates iron and contaminants, producing reusable hydrochloric acid and valuable by‑products like iron oxide. This closed‑loop system reduces waste, cuts operating costs, and supports cleaner steel production.

Acids Commonly Used in Pickling

Hydrochloric acid is the industry favourite because it works quickly and can be efficiently regenerated. Typical pickling concentrations range from 6% to 33% by weight. Other acids like sulfuric, nitric, and phosphoric are used in niche applications, but HCl remains dominant.

Why FRP Tanks Are Perfect for Acid Regeneration Plants

What Makes FRP Special?

FRP is a composite material made by reinforcing polymer resin with glass fibres. The result is a lightweight, high‑strength, corrosion‑resistant material that performs exceptionally well in aggressive chemical environments.

How FRP Tanks Are Built

- Filament Winding: Automated fibre placement for maximum strength.

- Hand Lay Up: Ideal for custom shapes and complex designs.

- Dual Laminate: A thermoplastic liner (PP, PVDF, etc.) combined with an FRP shell for superior chemical resistance.

Choosing the Right Resin

- Vinyl Ester: Best for hydrochloric and sulfuric acid service.

- Isophthalic Polyester: Suitable for moderate chemical exposure.

The Advantages of FRP Tanks — Explained Simply

Corrosion Resistance That Outperforms Steel and Concrete

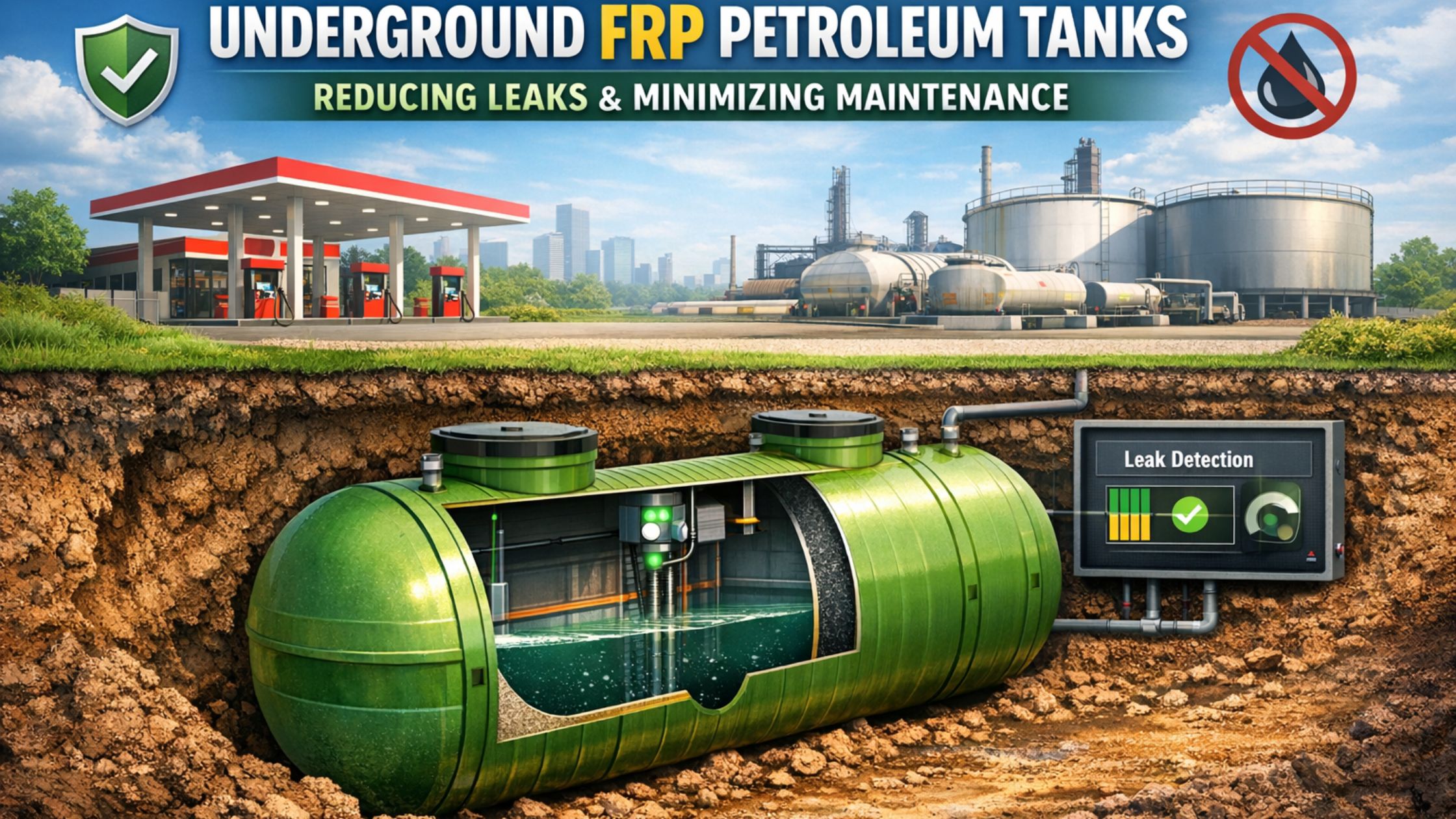

FRP doesn’t rust, pit, or scale. The resin matrix is chemically inert, making it ideal for HCl, FeCl₂, and other corrosive by‑products found in ARPs.

Steel tanks — even rubber lined ones — eventually corrode or suffer liner failures. Concrete tanks absorb chemicals and require constant repairs. FRP Tanks for Acid Regeneration Plants avoid all of these issues, making them a dependable long-term solution.

Long Service Life with Minimal Maintenance

A well‑designed FRP tank can easily last 20–30 years. Many installations continue performing reliably even beyond that, with only minor touch‑ups. In contrast, steel and rubber‑lined tanks often need replacement within 5–15 years.

Lightweight and Easy to Install

FRP tanks weigh up to 75% less than steel, which means:

- Lower transportation costs

- Smaller foundations

- Faster installation

- Easier site modifications

Lower Total Cost of Ownership

Even if the initial cost is slightly higher, FRP tanks save money over time through:

- Fewer repairs

- No corrosion related downtime

- Longer service life

Over 20 years, FRP tanks can reduce lifecycle costs by 30–50%.

Better Safety and Environmental Performance

FRP tanks offer:

- Non conductive construction r: reducing spark risks

- Seamless fabrication : fewer leak points

- No metal contamination : ensuring process purity

- Easier compliance with environmental regulations

Custom Engineered for Your Process

FRP tanks can be tailored to your exact needs:

- Vertical, horizontal, or rectangular designs

- Custom nozzle placements

- Manways, vents, scrubbers, level indicators

- Dual laminate options for extreme chemical environments

A More Sustainable Choice

FRP manufacturing has a lower carbon footprint than steel production. Longer service life and reduced maintenance further enhance sustainability — a growing priority for steel plants worldwide.

Quality You Can Trust: The FGPL Standard

At Fibro Grates Pvt. Ltd., every FRP tank goes through strict quality checks:

- Certified raw materials

- Structural and dimensional testing

- Non destructive inspections

- Compliance with ASTM, ASME, and BS EN standards

- Third party audits when required

Our tanks are already performing reliably in major steel and chemical plants across India, helping clients achieve safer operations using FRP Tanks for Acid Regeneration Plants engineered for demanding service environments.

Why FRP Tanks Are the Smart Choice for Steel Professionals

If you’re responsible for acid regeneration, pickling operations, or plant maintenance, FRP tanks offer clear advantages:

- Superior corrosion resistance

- Long, trouble free service life

- Lower total cost of ownership

- Safer, cleaner, more reliable operation

- Custom engineering for any process requirement

Conclusion: FRP Tanks Are the Future of Acid Regeneration

As steel manufacturers push for higher efficiency and sustainability, FRP tanks have become the logical choice for acid regeneration plants. Their durability, chemical resistance, and cost benefits make them a long‑term asset rather than a maintenance burden.

FGPL is proud to support the steel industry with high‑performance FRP solutions that stand the test of time.

Ready to upgrade your acid regeneration plant with FRP tanks? Reach out to FGPL at sales@fgpl.in, tarun@fgpl.in, cont. no. 7024130083 for a customized proposal and technical consultation.

Visit our website- FGPL