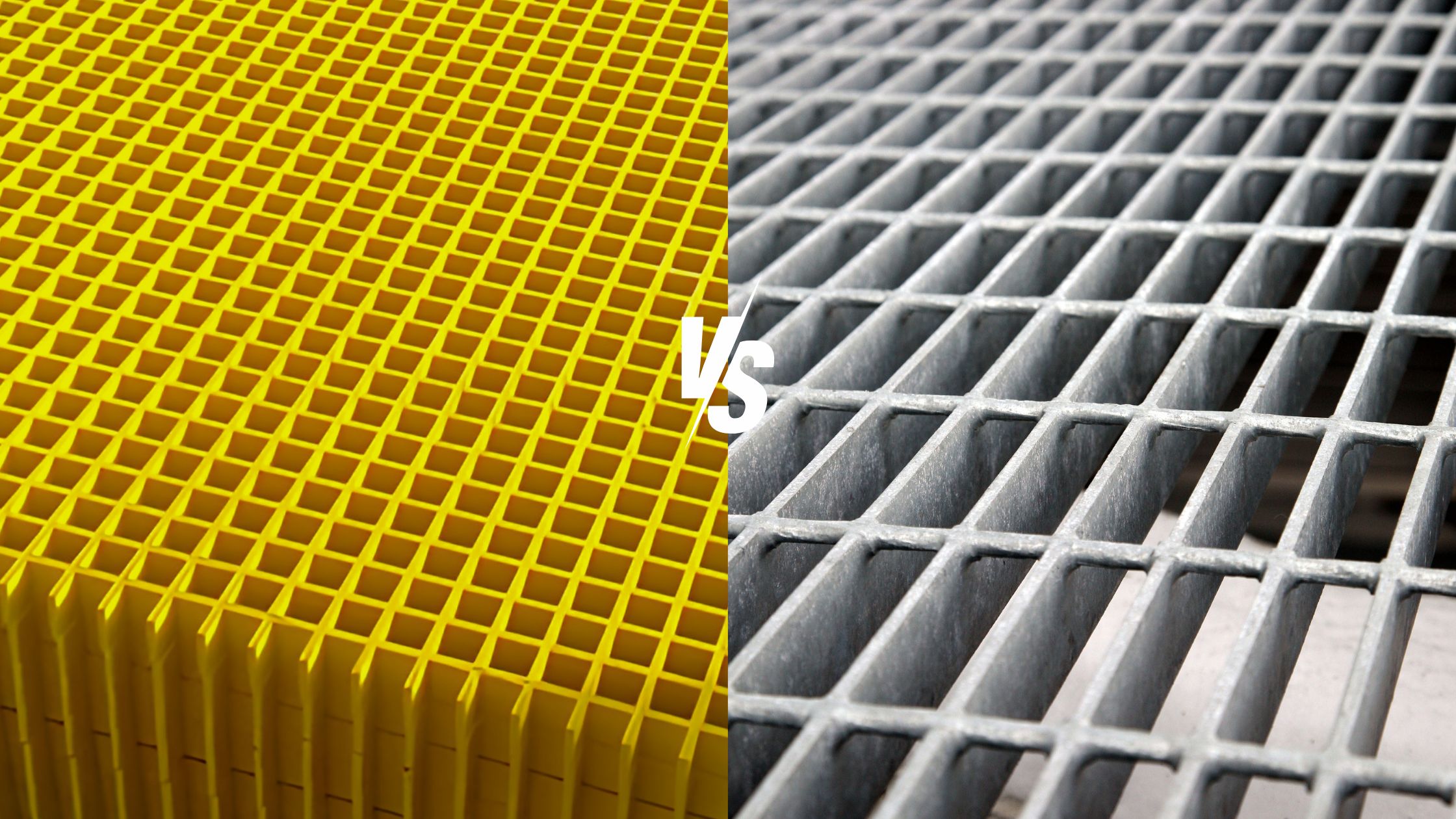

In industrial flooring and applications, the debate between using fiberglass grating versus metal gratings is pertinent, impacting decision-makers across industries. Fiberglass reinforced plastic grating, or FRP Grating, stands out as a superior choice for various reasons, encompassing its material composition, durability, cost efficiency, and safety features. The importance of selecting the right type of grating cannot be understated, as it directly affects operational efficiency, workplace safety, and long-term cost-effectiveness. Hence, the shift towards fiberglass grating in many sectors is a testament to its growing recognition and adoption by fiberglass grating suppliers and end-users alike.

This blog will explore the key factors that elevate fiberglass grating above traditional metal options, offering insights into its material composition and properties that contribute to its enhanced durability and strength. It will further delve into the cost efficiency and safety features of fiberglass grating, highlighting how these aspects make it a more viable and practical choice in the long run.

Additionally, the ease of installation and handling of fiberglass grating versus metal grating will be discussed, providing a comprehensive understanding of why FRP grating is increasingly preferred for use in a wide range of industrial applications.

Material Composition and Properties

Detailed Composition of FRP Gratings

FRP grating is crafted from a matrix of resin and reinforced fiberglass strands, offering superior corrosion resistance which is crucial in harsh environments. This composite material is not only robust against rust and degradation but also features excellent electrical insulation properties and non-magnetic characteristics, making it suitable for specialized applications. The production involves different types such as molded and pultruded grating, each providing unique characteristics like flame resistance or load-bearing capacity. Moreover, fiberglass grating is enhanced with additives like UV stabilizers and flame retardants to meet specific safety and durability standards

Comparison with Different Types of Metal Gratings

Metal gratings, typically made from steel, are known for their strength and load-bearing capabilities, making them ideal for heavy-duty industrial uses. However, they fall short in environments prone to corrosion and require regular maintenance to prevent rust. In contrast, FRP gratings offer a longer lifespan and lower maintenance costs due to their inherent resistance to corrosion, UV rays, and harsh chemicals. Additionally, fiberglass is significantly lighter than metal, reducing installation and transport costs, and does not require earthing due to its insulating properties. This makes FRP grating a cost-effective and durable alternative in many industrial applications.

Durability & Strength

Fiberglass grating demonstrates exceptional durability and strength, making it a preferred choice over metal gratings, especially in environments that challenge material integrity.

Fiberglass vs. Metal Gratings in Harsh Environments

Fiberglass reinforced plastic (FRP) grating thrives in harsh environments where metal gratings falter. Its resistance to corrosion, rust, and chemical exposure ensures longevity and reduces the need for frequent replacements. Unlike steel, which requires costly maintenance to prevent corrosion, FRP maintains its condition without additional protective measures. Moreover, fiberglass grating withstands extreme temperatures and harsh chemical environments outperforming metal in durability and cost-effectiveness over time.

Fatigue Resistance and Load-Bearing Capacities

While metal gratings are known for their load-bearing strength, FRP grating offers comparable strength with added benefits. The flexibility of fiberglass allows it to absorb impacts that would typically damage or dent metal, giving it superior fatigue resistance Additionally, despite its lighter weight, FRP grating supports considerable loads, making it suitable for a wide range of applications where weight reduction is crucial without compromising structural Integrity. This combination of durability and strength makes fiberglass grating a robust option for both industrial and commercial use.

Cost Efficiency

Initial Costs Vs. Long-Term Savings

While steel grating may appear more affordable initially due to its lower upfront costs, fiberglass grating often proves to be more cost-effective over time. The initial investment in fiberglass grating might be higher, but it offers significant long-term savings due to its durability and minimal maintenance requirements Factors like tariffs have also influenced cost perceptions, making fiberglass reinforced plastic (FRP) a competitive option as steel prices rise

Maintenance Expenses and Replacement Frequency

FRP grating requires considerably less maintenance compared to metal options, significantly reducing ongoing costs. Its resistance to corrosion, chemical exposure, and general wear extends its service life far beyond that of metal gratings, which often require frequent repairs and replacements Additionally, the lightweight nature of fiberglass reduces installation costs, and its non-corrosive properties eliminate the need for regular maintenance such as repainting, which is commonly required for steel grating. This not only lowers the total cost of ownership but also enhances operational efficiency by minimizing downtime.

Safety Features

FRP grating is recognized for its superior safety features compared to metal gratings, primarily due to its non-conductive and anti-slip properties. These characteristics make it highly suitable for environments where electrical hazards and slip resistance are critical.

Anti-Slip Properties of Both Materials

FRP grating is engineered with enhanced anti-slip surfaces, often incorporating special additives to increase traction, which significantly reduces the risk of slips and falls [1]. This feature is particularly beneficial in workplaces where the floor may become slippery due to moisture or industrial activities. In contrast, while steel grating also offers anti-slip properties due to its sturdy construction, fiberglass grating’s lightweight nature further minimizes the risk of injuries related to installation and handling, making it a safer option overall.

Fire Resistance and Toxicity Considerations

In terms of fire safety, fiberglass grating offers exceptional benefits. D.E.F.I. Phenolic FRP grating, for instance, is designed to be non-flammable and can withstand direct exposure to fire for extended periods without losing structural integrity. This makes it an ideal choice for areas prone to high fire risks, such as marine fire situations and platforms where evacuations might be necessary. Additionally, fiberglass grating produces very low smoke and toxic fume emissions when exposed to heat, contributing to safer evacuation conditions during an emergency.

Furthermore, the anti-slip properties of FRP grating are crucial for ensuring safety in various settings. Whether it’s for outdoor non-slip stair treads or industrial platforms, the material’s non-skid nature provides reliable footing, significantly reducing the likelihood of accidents. This aspect is especially important in high-traffic areas or environments where safety is a priority, such as marinas and public access points.

By integrating these safety features, FRP grating not only enhances workplace safety but also ensures a more durable and cost-effective solution for both indoor and outdoor applications.

Ease of Installation and Handling

Weight Differences and Installation Processes

FRP grating, known for its lightweight nature, significantly simplifies the installation process compared to heavier metal gratings. The reduced weight of fiberglass grating not only eases handling but also diminishes the need for heavy lifting equipment during installation. This advantage extends to reduced labor requirements and the potential for faster project completion, as the material can be easily moved and positioned by fewer workers. Additionally, the lightweight characteristic of fiberglass grating lessens the load on supporting structures, which may lead to cost savings in the structural design and construction phases.

Tool Requirements and Time Efficiency

The installation of FRP grating is facilitated by the use of simple hand tools, such as power saws for cutting to the desired size and shape, making it adaptable to various project requirements. Unlike metal gratings, which may require specialized tools for handling and installation due to their weight and rigidity, fiberglass grating can be easily cut and fitted on-site with basic equipment. This not only makes the installation quicker but also reduces the overall time and cost associated with the deployment of additional resources.

Moreover, the ease of maintenance, including straightforward cleaning with common cleaning agents like water and soap, further enhances the time efficiency associated with fiberglass grating, ensuring that it remains a practical and cost-effective solution in diverse environmental conditions

Conclusion

The comprehensive review of FRP grating establishes it as the superior choice over metal gratings for a variety of applications, from industrial flooring to complex environments where durability, strength, and safety are paramount. Through its material composition, FRP grating offers unmatched corrosion resistance, electrical insulation, and non-magnetic properties, hence providing a long-term, cost-effective solution. The implications of choosing fiberglass over metal extend beyond the immediate benefits of increased durability and reduced maintenance costs, highlighting a shift towards more sustainable and efficient construction and operational practices.

In essence, the adoption of fiberglass grating supports not only operational efficiency and workplace safety but also contributes to significant long-term savings and environmental benefits. The emphasis on its ease of installation, coupled with superior safety features such as anti-slip surfaces and fire resistance, underscores fiberglass grating’s role in enhancing the safety and sustainability of industrial and commercial spaces. As industries continue to recognize these advantages, the preference for fiberglass grating is expected to grow, further establishing its importance in modern construction and engineering solutions.

Also read: Elevate Your Industrial Space: Exploring the Benefits of FRP Grating for Flooring and Mezzanines

Follow us on Facebook: @fibrograts